By Bob Ciminel February 08, 2006

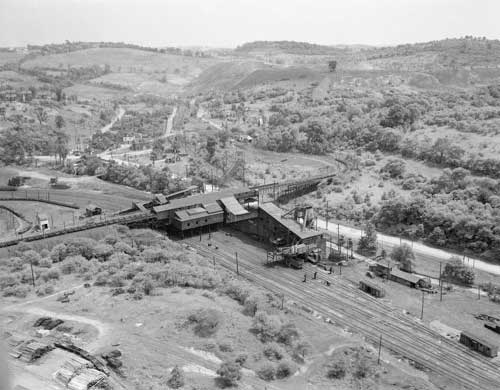

My mother's father worked in the mines owned by the Consolidation Coal Company in Frostburg, Maryland, near Cumberland. My paternal grandfather found work in the Idlewood mine operated by the Pittsburgh Coal Company. The high school I attended in the 1960's was built on the former site of the Idlewood mine. The school's driveway was located where a row of company houses once stood, one of which was my grandfather's home.

In those days, miners were contractors, not employees, and they were paid by the ton, not by the hour. Miners had to buy their own supplies, including blasting powder, and rented their homes from the coal company. Few miners were paid in cash; the coal companies preferred to issue scrip, which was only accepted at the company store. This was another way of keeping the work force tied to the mine. Having a captive work force also allowed many coal companies to realize sizeable profits from their stores and rental houses. In some cases, coal companies made more money from their stores and houses than they did from mining coal. The Pittsburgh Coal Company paid my grandfather 50 cents a ton for the coal he mined at Idlewood, but paid nothing for any slate or rock that had to be taken out. The Pittsburgh Seam consisted of an upper and lower coal measures separated by several inches of slate and shale. A layer of unstable sandstone called "top rock" was located above the coal seam and also had to be taken out to protect the miners from cave-ins. On average, the miners at Idlewood removed about two tons of slate, shale, and rock for each ton of coal they mined. Tennessee Ernie Ford's 1950's coal mining hit, "Sixteen Tons," didn't apply to the Idlewood miners; they had to load 48 tons to earn their $8.00 a day.

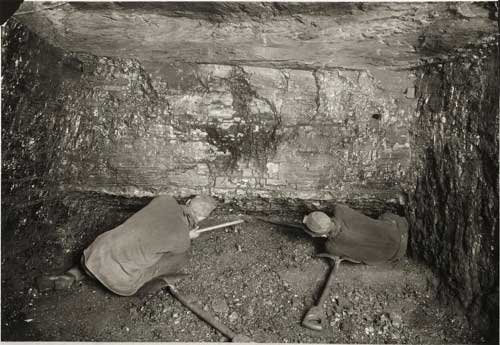

Coal was mined by hand after it was fractured using explosives. The miners began by using a hand-auger to drill holes diagonally into the coal at the face, or front of the room. Once the holes were drilled, the miners lay on their sides and used picks to cut a deep slot in the bottom of the coal face. This was called a "kerf." The kerf created a weak point in the coal seam. After packing the auger holes with black powder and a fuse, they were "tamped" with a foot or two of coal dust. Once all the holes were loaded, a shot firer, who was normally an employee of the coal company, came to fire the explosives. Many early mining disasters occurred when the miners would not wait for the shot firer and lit the fuses with their own lamps. This exposed the lamp flame to the air near the coal face, which might contain explosive concentrations of methane gas. Other disasters occurred when the miners did not properly tamp the auger holes and the flame and gases from the explosives caused coal dust to ignite in the room. However, in most cases, all went well and the combination of explosives and the weak point at the kerf would cause the coal to break into manageable lumps for loading. Mining accidents were common in the early days of coal mining, and labor was cheap. After one fatal accident, a mine superintendent was overheard saying, "Well, at least we saved the mules." As terrible as the recent accidents in West Virginia were, they pale in comparison to the carnage that went on in the coal mines of the early twentieth century. In 1907, more than 3,200 miners

died in our nation's coal mines; there were 28 fatalities in

2004, and the accident rate has averaged about 25 deaths per

year since 2002. When compared to the number of people employed

in the mines, the accident rate in 1907 was 5 deaths per 1,000

miners; in 2004 it was 0.25 per 1,000 miners. In 97 years, we've

reduced the fatal accident rate by 95%. Obviously, there is

still room for improvement, but short of using remote control

or robotic mining, with no one underground, we may not be able

to attain a fatality-free industry. On the Web:

He assumes informed readers will be able to tell the difference. ciminel@sitnews.us

|